Technologies For Innovation

SERVICES

After-sale service

+86 10-57374441

17

01

Comparison of High Frequency Induction Fusion Machine and Electric Fusion Machine

Ruishenbao Analytical (Tianjin) Co., Ltd

Key word: High, Frequency, Induction, Fusion, Machine,

In XRF analysis, glass fusion method has been developed and gradually matured since it is found in 1956, because it completely eliminates the mineral effect and granularity effect. What is more, the diluted sample reduces the matrix effect caused by the coexistent elements. Therefore the glass fusion method has now been adopted by a large number of laboratories around the world, and become one of the two methods of sample preparation for the XRF analysis.

Early glass fusion method often employed gas lamps or Mavericks, but now there are a large number of highly specialized and highly automated fusion machine. At present, the commonly used fusion machines are divided into three types according to the heating method: gas heated fusion machine, resistance radiation heated fusion machine, and high-frequency induction heated fusion machine. Due to the high demand for laboratory hardware(the need for stable supporting gas lines) and certain danger of high-heat gas, the gas heated fusion machine is not discussed here.

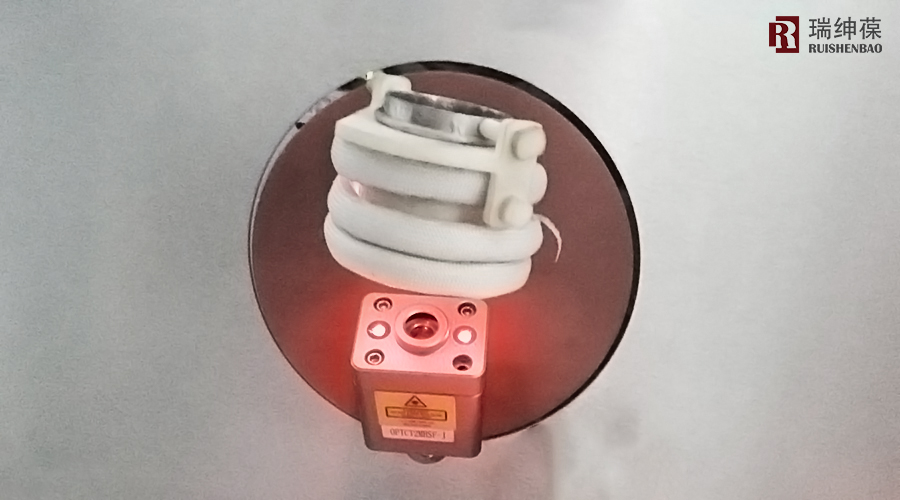

The principle of high-frequency induction heated fusion machine (high-frequency fusion machine in short) is that the high-frequency current generates the magnetic field by the coils to make the crucible's own resistance to generate Joule heat, so that the crucible itself can heat up for fusion.

The principle of resistance radiation heated fusion machine ( electrothermal fusion machine in short) is to use nickel-chromium Molybdenum resistance wire, Silicon carbon bar or Silicon Molybdenum bar, to heat up for fusion by electrothermal radiatio.

The high-frequency fusion machine is rarely used at present, so there are sevearal major misunderstandings in cognition listed below. We will make an explanation by comparison with electrothermal fusion machine.

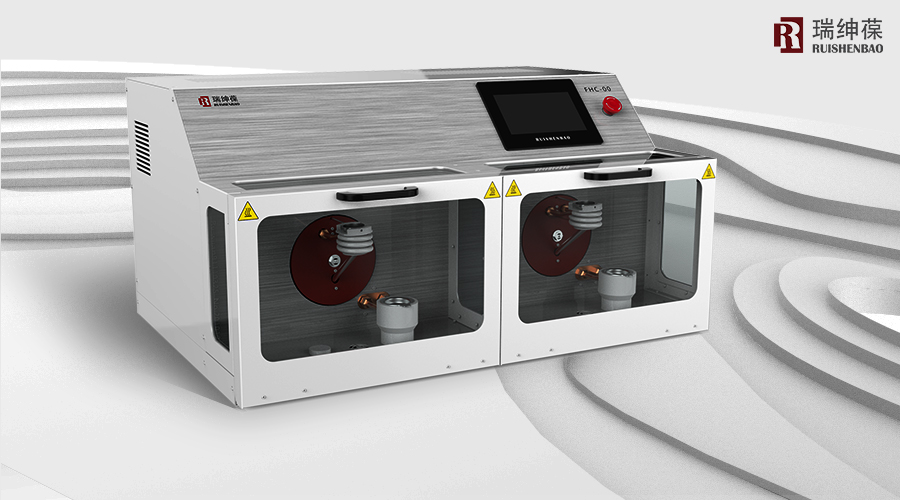

1. The temperature control accuracy can not meet the requirements: Compared with the electrothermal fusion machine (maximum temperature control ± 0.1℃), the high-frequency fusion machine does not have an advantage in temperature control accuracy. However, at present, the application of infrared temperature measurement no longer adopts the old-fashioned contact temperature measurement, and the temperature control accuracy is also getting higher and higher. In particular, RUISHENBAO FHC-00 high-frequency fusion machine has reached ± 1℃. Under the condition that the actual melt sample temperature is more than 1000 degrees, it can meet the daily sample production needs.

2. The temperature of each working position is inconsistent: This is due to the fact that some manufacturers' high-frequency fusion machine refer to the heating and temperature control system of the electrothermal fusion machine in series, resulting in the failure to accurately measure the temperature of each working position. At present, each position of RUISHENBAO FHC-00 high frequency fusion machine adopts independent heating and independent temperature measurement, which provide real feedback to the actual temperature of the working position.

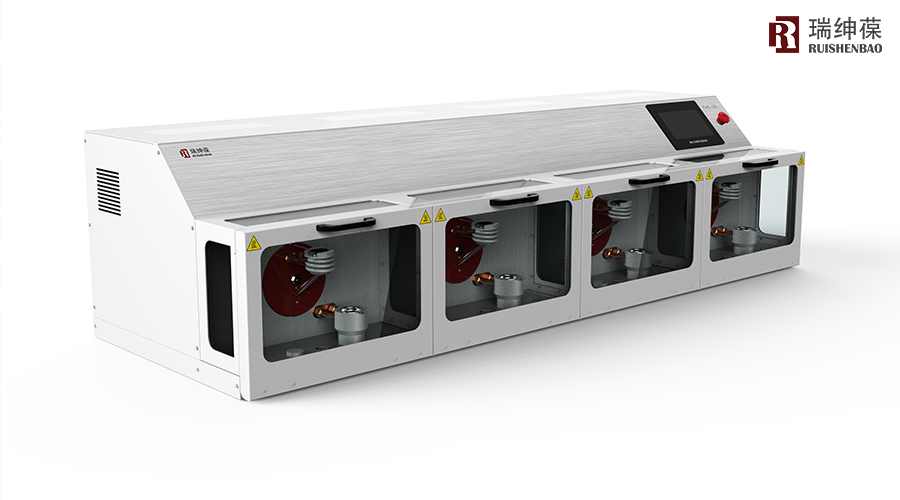

3. It is not suitable for mass sample preparation: This is attributed to the fact that multiple working positions may lead to inconsistent melt sample temperatures at over two ends. The existing high frequency fusion machine has two positions at most, and it is low in efficiency compared with the electrothermal fusion machine with four positions or even six positions. In fact, if the problem of work positions temperature control is solved, the low efficiency will be solved. At present, RUISHENBAO FHC-00 high-frequency fusion machine can posses a maximum of six positions. In combination with its advantage of rapid temperature increase, RUISHENBAO FHC-00 high-frequency fusion machine can get samples at the speed of 10 min/batch.

4. The crucible is easily worn: This is not correct. In fact, the crucible is mainly corroded by oxidizing substances in the sample. It can be solved by getting familiar with the sample nature in advance to reduce the oxide damage by pre-oxidation. At the same time, RUISHENBAO FHC-00 high frequency fusion machine adopts casting method to protect the crucible as much as possible.

5. Brackets generate slag: The slag is mainly caused by the oxidation of alloy brackets, but at present, RUISHENBAO FHC-00 high frequency fusion machine has already employed high-temperature ceramics to replace the high-temperature alloy to make brackets. Thus it is possible to completely avoid the slag contamination by the alloy brackets oxidation.

6. External circulating water is necessary: Compared with the electrothermal fusion machine, the high-frequency fusion machine requires supporting external circulating water. But at present it can be equipped with a special small water chiller with pure water which can be used for a long time. There is no need for external circulating water.

+86 10-57374441

+86 136 8188 9743

info@ruishenbao.com

Whatsapp:+86 13681889743

Skype:+86 13681889743

Room1006,No.280,ShangZhongXiLu,Xuhui district,ShangHai,200237,P.R.China

+86 10-57374441

+86 136 8188 9743

info@ruishenbao.com

Whatsapp:+86 13681889743

Skype:+86 13681889743

Room1006,No.280,ShangZhongXiLu,Xuhui district,ShangHai,200237,P.R.China